With the introduction of Ultra Low Sulfer Diesel (ULSD), new challenges have been created to improve the cold-weather operability of diesel fuel. These challenges are the primary reason we evaluate our cold-flow technology annually on the hardest-to-treat fuels to ensure our customers maintain the highest level of confidence in their partnership with Power Service.

When temperatures drop below zero, it is imperative you have the confidence you will be running trouble-free. Power Service has earned the confidence of the industry’s largest fleets and fuel marketers for over 50 years by providing the finest cold-flow technology available through continuous research and development.

Cold-Weather Operability

In June 2006, ULSD fuel was introduced for on-highway use and in June 2010 for off-road use, and contains a maximum of 15 ppm sulfur.

ULSD fuel burns cleaner by significantly reducing sulfur oxide emission and particulate matter, but it also has less solvency and higher paraffin (wax) content, making it harder to treat for winter operability.

To maximize ULSD fuel performance in cold temperatures, Power Service has developed, through hours of testing and research, the most advanced cold-flow improver technology available today for all diesel fuels, including biodiesel blends containing up to 20% biodiesel (B20).

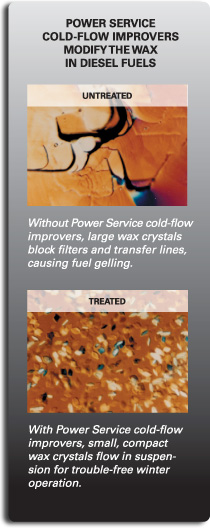

Power Service cold-flow improvers are designed to prevent fuel-filter plugging by modifying the size and shape of the wax crystals so they remain small enough to flow through fuel-filters without plugging in the coldest temperatures for trouble-free operation during winter months. Water or condensation buildup is very common in ULSD.

When temperatures fall below 30°F., the water can separate or fall out of solution and freeze on the facings of fuel-filters, preventing fuel flow.

To address this issue, we formulate all of our cold-fl ow improver packages to include a non-alcohol de-icer to help prevent fuel-filter and fuel line freezing caused by water.

ow improver packages to include a non-alcohol de-icer to help prevent fuel-filter and fuel line freezing caused by water.

Power Service manufactures a full line of cold-flow improvers to meet your needs, including those fuels blended with biodiesel up to 20%. Additionally, our cold-flow improver package is formulated to provide the benefits of +Cetane Boost® for faster cold starts, Slickdiesel® Lubricator and HPCR Detergent Technology to keep injection systems operating at peak performance during winter months.

There are several winter operability tests performed in the Power Service Technical Services Laboratory. These include:

- Cloud Point (CP) – As diesel fuel cools, the soluble paraffin wax naturally found in diesel fuel begins to form crystals and gives the fuel a cloudy appearance. The fuel’s Cloud Point usually occurs between + 20°F. and 0°F.

- Cold-Filter Plugging Point (CFPP) – This is the highest temperature at which diesel fuel, when cooled, will stop flowing through a prescribed filter element. The wax crystals have agglomerated and become too large to flow through the filter and the engine stops.

- Pour Point (PP) – Pour Point is the lowest temperature at which the fuel will still pour. The Pour Point will occur at temperatures below the CFPP and operability temperature of the fuel.